What Is a Recovery Board in Roofing? Uses, Benefits, and Best Practices

When roofing systems reach the end of their lifespan, property owners face a key decision: full tear-off or roof recovery. Recovery board has become a smart alternative, allowing new roofing systems to be installed over existing ones while preserving structural integrity and meeting code requirements.

This method cuts project costs by up to 40%, reduces disruption, and avoids sending tons of roofing waste to landfills. As a core layer in roof overlays, recovery board creates a smooth, stable base for new roofing materials. It solves issues common to deteriorated substrates, making it easier to install reliable systems without a full replacement.

With evolving building codes favoring sustainable practices, recovery board use has expanded across a variety of roofing needs. Premier Roofing emphasizes the importance of proper selection, installation, and maintenance. When done right, recovery board systems not only extend roof life but also enhance performance and energy efficiency, helping property owners get more from their investment.

Understand the Basics of the Recovery Board for Smarter Roofing Decisions

Recovery board, also known as overlay board or recover board, is a specially engineered substrate material designed to create a suitable foundation for new roofing systems when installed over existing roofs. Unlike traditional roof decking materials, recovery boards are specifically manufactured to address the unique challenges that arise when working with aged or deteriorated roofing surfaces.

The primary function of the recovery board extends beyond simply providing a flat surface. These specialized panels are engineered to bridge minor depressions, provide thermal resistance, and create proper drainage slopes while maintaining compatibility with various membrane types.

Modern recovery boards typically range from 0.5 inches to 2 inches in thickness, depending on the specific application requirements and existing roof conditions. Most recovery board systems incorporate closed-cell foam cores or high-density polyisocyanurate insulation, which provides both structural support and enhanced thermal performance.

The facing materials vary based on the intended roofing system, with options including fiberglass mats, synthetic facers, and specialized coatings designed to promote adhesion with specific membrane types. At Premier Roofing, we’ve observed that properly specified recovery board systems can extend roof life by 15-20 years compared to direct overlay applications.

Choose the Right Recovery Board Material for Lasting Performance

The roofing industry offers several distinct categories of recovery board, each engineered for specific applications and performance requirements. Polyisocyanurate recovery boards represent the most common option, featuring rigid foam cores with R-values ranging from 5.6 to 8.0 per inch of thickness. These boards excel in applications requiring both insulation enhancement and substrate preparation.

Expanded polystyrene (EPS) recovery boards provide an economical alternative for projects where thermal performance is less critical. EPS boards typically offer R-values between 3.8 and 4.2 per inch while maintaining excellent dimensional stability and moisture resistance. The lower density of EPS makes these boards easier to handle during installation, reducing labor costs and installation time.

Composite recovery boards combine multiple materials to achieve specific performance characteristics. These systems might incorporate mineral fiber cores for enhanced fire resistance, or they may feature graduated density profiles that provide superior fastener retention in the top layer while maintaining cost-effectiveness in the lower sections.

Wood fiber recovery boards, while less common in modern applications, still find use in specialized situations where traditional materials are preferred or required by local building codes.

Install Recovery Board Correctly for Maximum Roof Longevity

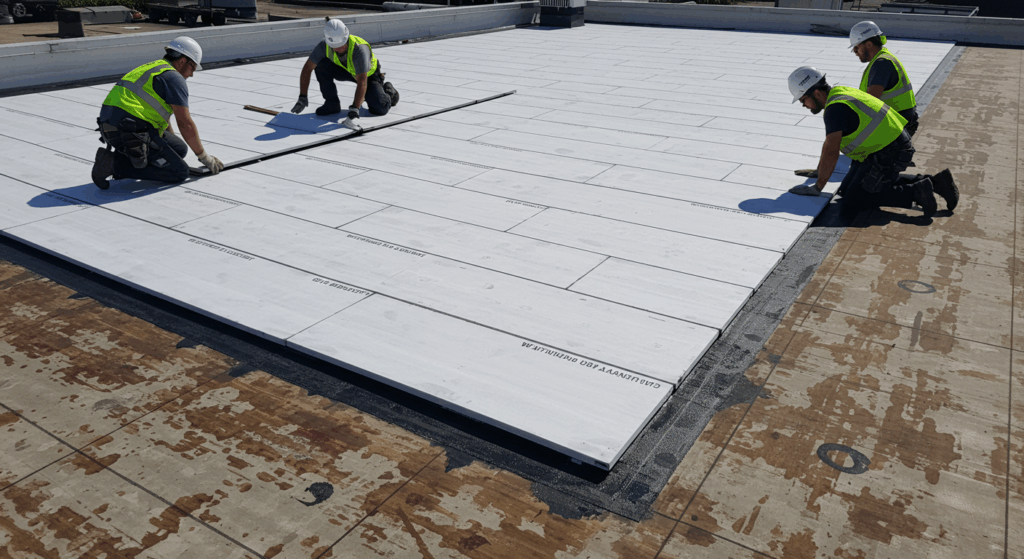

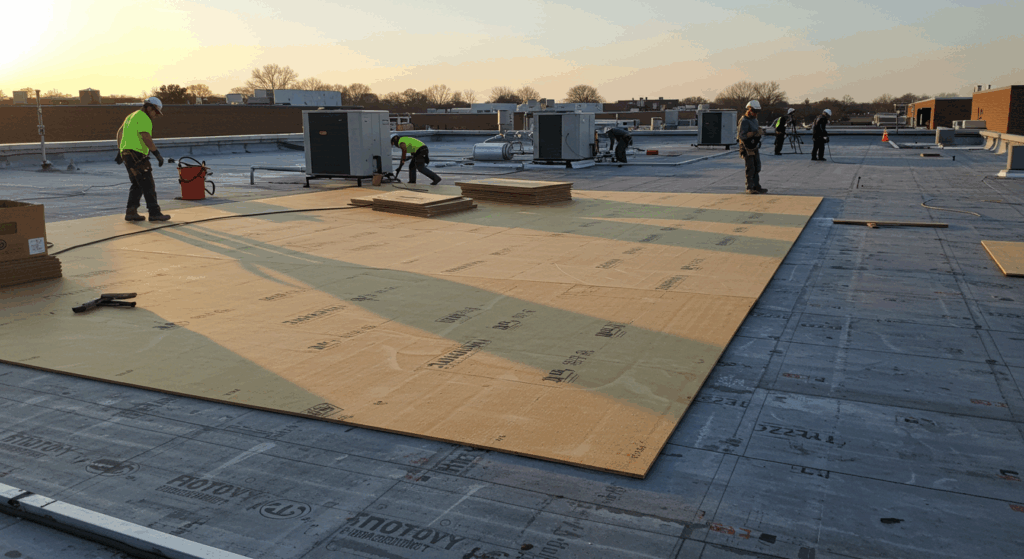

Proper installation of recovery board systems requires meticulous attention to substrate preparation and environmental conditions. The existing roof surface must be thoroughly cleaned of loose debris, ponding water, and any protruding fasteners that could create puncture points.

Surface irregularities exceeding 0.25 inches typically require correction through grinding, patching, or selective removal before recovery board installation begins. Fastening patterns for recovery board installation vary significantly based on board type, thickness, and wind load requirements.

Most installations require mechanical fasteners spaced 12 inches on center along board edges and 24 inches on center in the field area. However, high-wind zones or specialized applications may require fastener spacing as tight as 6 inches on center to meet code requirements.

Joint treatment represents a critical aspect of recovery board installation that directly impacts long-term performance. Board joints must be staggered to prevent alignment with existing substrate joints, and gaps between boards should not exceed 0.25 inches.

Many installations incorporate joint sealants or tape systems to prevent air infiltration and moisture penetration. Temperature considerations during installation are equally important, as thermal expansion and contraction can create stress points if boards are installed during extreme temperature conditions.

A notable project completed in Denver during 2023 demonstrated the importance of proper installation techniques when a 150,000-square-foot warehouse facility required roof recovery. The project team discovered that the existing membrane had multiple punctures, and the substrate showed significant weathering.

By implementing a systematic recovery board installation with enhanced fastening patterns, the facility achieved a 25-year warranty on the new system while reducing overall project costs by $180,000 compared to complete tear-off alternatives.

Unlock Cost, Energy, and Performance Gains with Recovery Board

Recovery board systems deliver substantial cost advantages that extend far beyond initial material savings. Labor costs typically decrease by 30-50% compared to tear-off projects because crews avoid the time-intensive processes of membrane removal, debris handling, and disposal coordination.

Additionally, the reduced project timeline minimizes business disruption, which can represent significant value for commercial operations that cannot afford extended shutdowns. Environmental benefits of recovery systems align with increasingly important sustainability goals. A typical 50,000-square-foot commercial roof generates approximately 200 tons of waste material during tear-off operations.

Recovery board applications eliminate this waste stream while extending the useful life of existing structural components. The enhanced insulation properties of most recovery board systems also contribute to improved energy efficiency, with many installations achieving 15-25% reductions in heating and cooling costs.

Performance advantages include improved thermal consistency across the roof surface and enhanced protection against thermal shock. Recovery boards create a buffer layer that protects new membrane systems from substrate movement and temperature fluctuations that commonly cause premature membrane failure. The additional thickness also provides improved puncture resistance and creates opportunities for enhanced drainage design in areas with existing slope deficiencies.

See Where the Recovery Board Works Best Across Roof Types

Commercial flat roof recovery represents the largest segment of recovery board applications, particularly in retail, warehouse, and office building sectors. These applications typically involve installing a recovery board over aged EPDM, TPO, or built-up roofing systems that have reached the end of their warranty periods but maintain structural integrity.

The recovery approach allows building owners to upgrade to newer membrane technologies while preserving existing insulation and deck investments. Residential applications have grown significantly since 2020, particularly in markets with high disposal costs or environmental regulations.

Low-slope residential roofs, including those found on condominiums, townhomes, and mixed-use developments, often benefit from recovery board solutions when traditional steep-slope options are not feasible. These applications frequently incorporate enhanced insulation properties to meet evolving energy codes.

Specialized applications include recovery systems designed for vegetative roofs, solar installations, and high-wind coastal environments. Each application requires specific board characteristics and installation modifications to address unique performance requirements.

For example, solar-ready recovery boards incorporate enhanced fastener pullout resistance and dimensional stability to support mounting systems over extended service periods.

Know the Limitations of the Recovery Board Before You Install

While recovery board systems offer numerous advantages, certain limitations must be carefully evaluated during the planning phase. Building height restrictions may prevent recovery applications in areas with strict zoning requirements, as the additional thickness can push total building height beyond allowable limits.

Most recovery board installations add 1-3 inches to overall roof height, which may impact equipment clearances, parapet relationships, and architectural details. Structural load considerations require professional evaluation to ensure existing roof framing can support the additional dead load imposed by recovery board systems.

Typical recovery boards add 0.5 to 2.0 pounds per square foot of dead load, which may exceed the reserve capacity of older buildings or structures designed with minimal safety factors. Load calculations must account for snow loads, equipment loads, and any future modifications planned for the roof system.

Warranty complications can arise when recovery systems are installed over existing roofs with undisclosed problems. Moisture trapped beneath recovery boards can cause accelerated deterioration of underlying materials, leading to warranty disputes and performance issues.

Comprehensive moisture surveys and substrate evaluations are essential to identify potential problems before recovery board installation begins. Premier Roofing recommends infrared moisture scans and core sampling for all recovery projects to establish baseline conditions and identify areas requiring remediation.

Maintain Recovery Board Systems to Extend Their Lifespan

Successful recovery board installations require comprehensive quality control programs that address both material specifications and installation procedures. Board delivery and storage procedures must protect materials from moisture infiltration and physical damage that could compromise performance.

Most manufacturers require specific storage conditions and installation timeframes to maintain product warranties. Post-installation maintenance programs for recovery board systems differ from traditional roof maintenance due to the additional substrate layer.

Standard maintenance activities include regular inspections of fastener patterns, joint integrity, and surface conditions. Particular attention must be paid to areas around roof penetrations, where recovery board details are most vulnerable to moisture infiltration and wind uplift.

Long-term performance monitoring should include periodic infrared surveys to detect moisture infiltration and thermal bridging issues that may develop over time. Annual inspections should document any changes in surface conditions, fastener security, and joint performance. Preventive maintenance programs typically extend recovery board system life by 20-30% compared to reactive maintenance approaches.

Documentation requirements for recovery board systems exceed those of traditional roofing installations due to warranty considerations and future renovation planning. Complete installation records should include substrate conditions, moisture survey results, fastening patterns, and material certifications. This documentation proves invaluable during warranty claims and provides essential information for future roof modifications or replacements.

Frequently Asked Questions

What is the typical lifespan of a recovery board roofing system?

Recovery board systems typically last 20-25 years when properly installed and maintained. The actual lifespan depends on factors including membrane type, climate conditions, maintenance quality, and substrate conditions at installation.

High-quality recovery board installations with premium membrane systems often achieve 30-year performance in moderate climates, while harsh environments may reduce expected life to 15-20 years.

Can a recovery board be installed over any existing roofing material?

The recovery board cannot be installed over all existing roofing materials. Suitable substrates include structurally sound EPDM, TPO, modified bitumen, and built-up roofing systems.

The recovery board should not be installed over deteriorated substrates, wet insulation, or roofs with significant structural problems. Professional evaluation is essential to determine substrate suitability and identify areas requiring repair before recovery board installation.

How much does recovery board installation cost compared to complete roof replacement?

Recovery board installations typically cost 40-60% less than complete tear-off and replacement projects. A typical commercial recovery board project ranges from $4-8 per square foot, while complete replacement often costs $8-15 per square foot.

Cost savings result from reduced labor requirements, eliminated disposal fees, and shorter project timelines. However, costs vary significantly based on geographic location, project size, and specific system requirements.

What building code requirements apply to recovery board installations?

Recovery board installations must comply with local building codes regarding structural loads, fire ratings, and wind uplift resistance. Most codes limit the number of roof layers to two or three total systems, including the recovery installation.

Wind uplift requirements often increase fastening density and edge details compared to new construction. Professional design is typically required to ensure code compliance and proper structural evaluation.

How do you prevent moisture problems with recovery board systems?

Moisture prevention requires thorough substrate evaluation before installation, proper vapor barrier design, and comprehensive joint sealing. Pre-installation moisture surveys identify wet areas that require drying or removal before recovery board placement.

Proper drainage design prevents water accumulation, while quality installation techniques ensure weather-tight joints and penetration details. Regular maintenance and inspections help identify and address moisture issues before they cause significant damage.

Plan a Successful Roof Recovery with Proven Expertise

Recovery board systems represent a proven, cost-effective solution for extending roof life while meeting modern performance standards and environmental goals. The key to successful recovery board implementation lies in thorough substrate evaluation, proper material selection, and professional installation techniques that address the unique requirements of each project.

When properly executed, recovery board installations deliver decades of reliable performance while providing substantial cost savings and environmental benefits compared to traditional tear-off approaches.

Property owners considering recovery board solutions should work with experienced roofing professionals who understand the complexities of substrate preparation, code compliance, and long-term maintenance requirements to ensure optimal results from their roofing investment.

About Premier Roofing

Premier Roofing delivers commercial and residential roofing solutions backed by over 15 years of experience. We offer recovery board installations, membrane systems, and full roof replacements. Our certified team combines roofing expertise with proven techniques to deliver durable, cost-effective results.

We take a structured approach to roof evaluation, installation, and warranty coverage, protecting your investment long-term. Our recovery board specialists have completed hundreds of overlay projects, helping clients save money while extending roof life and improving performance. From inspection to final walkthrough, we meet or exceed all code and quality standards.Contact our team today to discuss how our roofing expertise can help you determine if recovery board installation is the right solution for your property. Schedule a consultation to learn more about our recovery systems and how we’ve helped clients achieve substantial savings while improving roof performance and longevity.