Roof Penetration Details That Make or Break Your Flat Roof

When you think about what keeps your building protected, you likely picture the main roofing membrane. But the biggest weakness on any flat roof isn’t the membrane, it’s the penetrations. Pipes, vents, HVAC units, and other equipment that puncture the roof create potential entry points for water. Poor penetration details are behind over 75% of flat roof failures, according to 2024 industry data.

These penetrations range from small vents to massive HVAC units. While all are essential, they also pose serious waterproofing risks. They require careful attention during installation and ongoing maintenance to prevent leaks. Even minor errors can result in long-term damage if flashing, materials, or sealing strategies are overlooked.

That’s where Premier Roofing brings value. The difference between a watertight system and one prone to failure often comes down to getting penetration details right the first time. With the right techniques and maintenance in place, your roof can perform reliably for decades.

Identify and Address Risk Points in Flat Roof Penetrations

Every commercial and residential flat roof features multiple penetrations, each presenting unique sealing challenges. The most common types include plumbing vents, HVAC equipment, electrical conduits, and rooftop access hatches. Each penetration type requires specific detailing approaches based on its size, movement characteristics, and exposure to weather elements.

Small penetrations like plumbing vents typically measure 2-4 inches in diameter and remain relatively stationary. These seemingly simple features can cause major problems when installers use inadequate flashing or fail to properly integrate the seal with the roofing membrane.

Medium-sized penetrations, such as exhaust fans and electrical equipment, range from 6-24 inches and often experience thermal movement that can stress traditional sealing methods. Large penetrations present the greatest challenge, particularly HVAC units that can weigh thousands of pounds and create significant roof deflection.

These installations require engineered support systems and sophisticated flashing details that account for both structural loads and thermal movement. Premier Roofing specializes in handling these complex penetration challenges across all flat roofing systems.

The location of penetrations also affects their vulnerability. Equipment placed in drainage areas faces increased water exposure, while penetrations on exposed roof areas endure more severe thermal cycling and UV degradation.

Install Flashing Correctly to Prevent Water Intrusion

Proper flashing represents the first line of defense against water infiltration at roof penetrations. Base flashing forms the foundation of any penetration detail, extending from below the roofing membrane up the sides of the penetrating element. This component must integrate seamlessly with the roof membrane while providing a watertight seal that accommodates building movement.

Counter flashing creates the secondary barrier, typically installed over the base flashing and sealed directly to the penetrating element. The overlap between base and counter flashing creates a shingle effect that directs water away from potential entry points. Professional installers understand that this overlap must measure at least 4 inches to provide adequate protection under wind-driven rain conditions.

The installation sequence proves critical to long-term performance. Base flashing must be installed before the final roof membrane application, allowing for proper integration and heat welding on thermoplastic systems. Counter flashing installation follows membrane completion, with careful attention to sealant application and mechanical fastening schedules.

Material compatibility between flashing components and the roof membrane prevents premature failures. EPDM systems require EPDM-compatible flashing materials, while TPO and PVC membranes demand thermoplastic flashing that can be heat-welded for permanent bonds. Mixed material systems often fail within the first five years due to incompatible expansion rates and chemical interactions.

Choose Flashing Materials That Stand the Test of Time

The choice of flashing materials directly impacts penetration longevity and maintenance requirements. Lead-coated copper remains the gold standard for durability, offering 40+ years of service life with minimal maintenance. However, cost considerations and installation complexity often drive contractors toward alternative materials that may compromise long-term performance.

Stainless steel flashing provides excellent corrosion resistance and thermal stability, making it ideal for high-temperature applications like exhaust vents and kitchen hoods. The material’s low expansion coefficient reduces stress on sealant joints during thermal cycling. However, stainless steel requires specialized cutting tools and installation techniques that increase labor costs.

Thermoplastic flashing materials offer superior integration with TPO and PVC membrane systems through heat welding. These materials eliminate reliance on sealants for primary waterproofing, creating permanent bonds that won’t degrade over time. The key advantage lies in the ability to create monolithic seals that move as a unit with the roof membrane.

Modified bitumen and EPDM-compatible flashing materials provide cost-effective solutions for budget-conscious projects. While these materials may require more frequent maintenance intervals, proper installation and regular inspection can deliver 15-20 years of reliable service.

The critical factor lies in selecting materials from reputable manufacturers who provide compatibility warranties with specific membrane systems.

Account for Thermal Movement to Prevent Future Failures

Flat roof penetrations experience significant thermal stress as building materials expand and contract with temperature changes. A typical rooftop HVAC unit can move up to 1/2 inch in any direction during extreme temperature swings, placing enormous stress on rigid flashing details. Understanding and accommodating this movement represents a crucial aspect of successful penetration design.

Expansion joints at large penetrations provide relief for thermal stress while maintaining waterproof integrity. These specialized details incorporate flexible materials that compress and extend with building movement while preserving the seal integrity. Proper expansion joint design requires careful calculation of expected movement ranges based on local climate conditions and equipment specifications.

Base isolation techniques separate penetrating equipment from direct roof membrane contact, reducing stress transmission during thermal cycling. This approach typically involves creating a raised curb system with integral flashing that supports the equipment while protecting the membrane below. The curb height must exceed the roof’s flood level while providing adequate clearance for membrane maintenance.

Flexible sealant selection becomes critical in high-movement applications. Structural glazing sealants offer superior adhesion and movement capability compared to standard construction sealants, though they require specific surface preparation and application techniques. These premium sealants can accommodate +/-50% joint movement while maintaining weatherproof seals for 20+ years.

Avoid Installation Errors That Lead to Early Roof Failure

Poor penetration details stem from several recurring installation errors that create immediate vulnerabilities or long-term failure patterns. Inadequate surface preparation ranks as the leading cause of sealant failure, with contaminated or improperly primed surfaces preventing proper adhesion. This seemingly minor oversight can lead to complete seal failure within the first year of service.

Insufficient flashing overlap creates direct water entry paths during wind-driven rain events. Many contractors reduce material costs by minimizing flashing dimensions, not realizing that a few inches of additional material can prevent thousands of dollars in water damage. Industry standards specify minimum 4-inch overlaps, but experienced installers often exceed these requirements in critical applications.

Improper fastening patterns compromise both immediate and long-term performance. Over-driven fasteners create stress concentrations that tear flashing materials, while under-driven fasteners allow water infiltration around fastener penetrations. The fastening schedule must account for local wind loads, thermal movement, and material characteristics to ensure optimal performance.

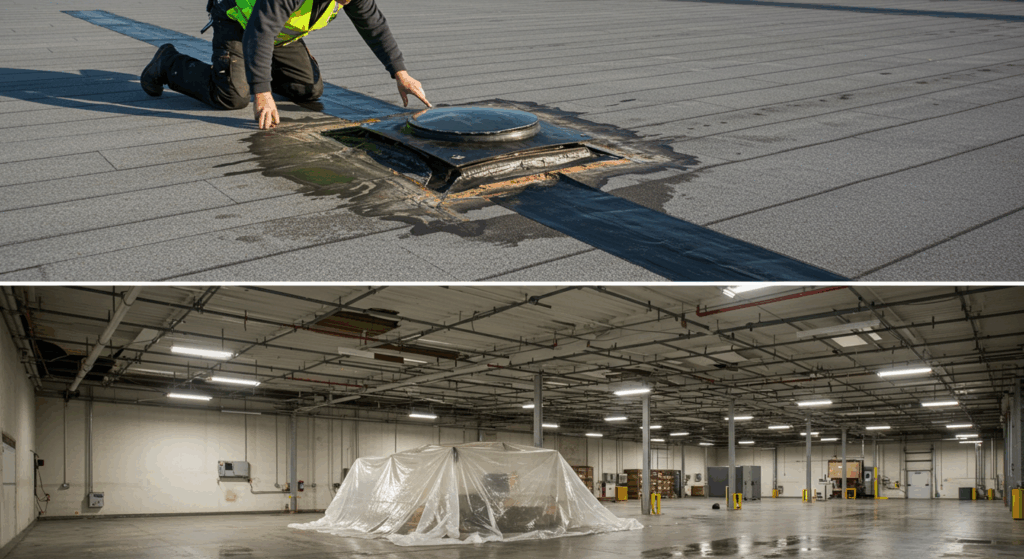

One of our recent projects involved repairing a 50,000-square-foot warehouse where improper HVAC penetration details led to extensive interior damage. The original contractor had used incompatible materials and failed to provide adequate thermal movement accommodation.

Our team redesigned the penetration details using thermoplastic flashing systems with integrated expansion joints, eliminating the recurring leak issues that had plagued the facility for three years.

Extend Roof Life with Regular Penetration Maintenance

Regular inspection and maintenance programs can extend penetration service life by identifying and addressing minor issues before they become major problems. Semi-annual inspections should focus on sealant condition, flashing integrity, and signs of water infiltration. Early detection of hairline cracks or minor adhesion loss allows for cost-effective repairs that prevent extensive damage.

Sealant refresh schedules depend on material type and exposure conditions, but most applications benefit from proactive renewal every 7-10 years. This preventive approach costs significantly less than emergency repairs and helps maintain warranty coverage on roofing systems.

Professional maintenance programs track individual penetration performance and schedule renewals based on actual condition rather than arbitrary timeframes. Drainage maintenance around penetrations prevents water accumulation that accelerates material degradation.

Roof drains and scuppers require regular cleaning to ensure proper water flow, while ponding areas near penetrations may require additional drainage improvements. Premier Roofing offers comprehensive maintenance programs that address both immediate needs and long-term performance optimization.

Equipment replacement planning should coordinate with penetration renewal to maximize cost efficiency. When HVAC units reach end-of-life, the penetration details typically require complete renewal to accommodate new equipment specifications. This coordination prevents the need for separate roof work and ensures optimal integration between new equipment and existing roof systems.

Use Modern Sealing Methods for Complex Penetration Needs

Modern roofing technology offers sophisticated solutions for challenging penetration applications that exceed traditional flashing capabilities. Liquid-applied membranes provide seamless transitions around complex geometric shapes that would be difficult to flash with conventional materials. These systems cure in place to create custom-fitted seals with excellent adhesion and flexibility characteristics.

Prefabricated penetration boots eliminate many field installation variables while providing consistent quality and performance. These factory-manufactured components integrate multiple flashing elements into a single assembly that reduces installation time and potential error sources. However, proper sizing and membrane compatibility remain critical for successful application.

Hybrid sealing systems combine mechanical and chemical attachment methods for maximum reliability in critical applications. These approaches typically feature mechanically attached base flashing with chemical-bonded overlay systems that provide redundant protection.

While more expensive than conventional details, hybrid systems offer superior performance in high-consequence applications. Self-adhering flashing tapes have revolutionized small penetration sealing by eliminating heat welding requirements while providing permanent bonds.

These advanced materials incorporate aggressive adhesive systems that create immediate seals without curing time or temperature restrictions. Professional-grade tapes offer 20+ year service life with minimal maintenance requirements when properly applied to clean, dry surfaces.

Match Penetration Details to Membrane Type for Best Results

Each flat roof membrane type requires specific penetration detailing approaches to ensure compatibility and optimal performance. EPDM systems rely heavily on adhesive-bonded connections that require precise surface preparation and environmental conditions during installation.

The key to successful EPDM penetration details lies in creating adequate bond areas with proper cleaning and priming procedures. Thermoplastic membranes like TPO and PVC offer superior penetration sealing through heat welding technology that creates permanent, maintenance-free bonds.

These systems eliminate reliance on sealants for primary waterproofing while providing excellent long-term performance. However, welding equipment and operator certification requirements increase installation complexity and cost.

Modified bitumen systems accommodate penetrations through torch-applied or cold-adhesive methods that integrate well with traditional flashing materials. These systems offer excellent self-sealing properties around fastener penetrations while providing familiar installation procedures for experienced contractors.

The multi-ply construction provides inherent redundancy that enhances penetration reliability. Built-up roofing systems require specialized penetration details that account for the multi-layer construction and hot asphalt installation methods.

Proper sequencing ensures each membrane ply properly integrates with flashing components while maintaining the system’s vapor barrier integrity. These systems often provide the most economical solution for large commercial applications with numerous penetrations.

Frequently Asked Questions

What is the most common cause of flat roof leaks related to penetrations?

Poor flashing installation accounts for approximately 75% of penetration-related leaks, specifically, inadequate overlap between base and counter flashing components. When these elements don’t properly shed water away from the penetration, moisture finds entry points that lead to interior damage and membrane deterioration.

How often should roof penetration seals be inspected?

Professional inspections should occur twice annually, ideally in spring and fall, with additional checks following severe weather events. Property owners should also perform monthly visual inspections from ground level, looking for obvious signs of damage or displaced flashing components that require immediate attention.

Can I repair penetration leaks myself, or do I need professional help?

While minor sealant touch-ups might seem manageable, penetration repairs typically require specialized materials, tools, and expertise to ensure long-term effectiveness. Improper DIY repairs often void manufacturer warranties and can create larger problems that cost significantly more to address than professional repairs would have initially.

What’s the expected lifespan of different penetration flashing materials?

Lead-coated copper flashing can last 40+ years with minimal maintenance, while stainless steel typically provides 25-30 years of service. Thermoplastic materials offer 20-25-year lifespans when properly installed, and modified bitumen flashing generally requires renewal every 15-20 years, depending on exposure conditions and maintenance quality.

How do I know if my roof penetrations need immediate attention?

Warning signs include visible water stains on interior ceilings near equipment, loose or damaged flashing materials, cracked sealant joints, ponding water around penetrations, and any penetration that shows daylight when viewed from below. Any of these conditions warrants immediate professional evaluation to prevent extensive damage.

Plan for Long-Term Protection with the Right Penetration Strategy

The success of your flat roof system depends heavily on the quality and attention given to penetration details during installation and throughout the roof’s service life.

While these components represent a small percentage of the total roof area, they require the highest level of expertise and quality materials to ensure long-term performance. Proper penetration design accounts for thermal movement, material compatibility, drainage patterns, and maintenance accessibility to create systems that protect your building investment for decades.

The upfront investment in quality penetration details pays dividends through reduced maintenance costs, extended roof life, and protection of valuable interior assets from water damage.

About Premier Roofing

Premier Roofing brings over 15 years of experience in commercial and residential flat roofing, serving property owners throughout the region. We offer full-service solutions including penetration design, emergency leak repairs, and preventive maintenance. Our certified professionals combine hands-on skills with industry knowledge to deliver durable, watertight results.

We pride ourselves on meticulous attention to penetration details and have helped hundreds of clients eliminate recurring leak problems through proper flashing installation and material selection. Our services include EPDM, TPO, PVC, and modified bitumen systems, with specialized expertise in complex penetration challenges involving HVAC equipment, plumbing systems, and rooftop access features.Contact our team today to discuss how our flat roofing expertise can help you achieve long-lasting protection for your building. Schedule a consultation to learn more about our penetration sealing services and how we’ve helped clients achieve decades of leak-free performance through proper installation and maintenance practices.