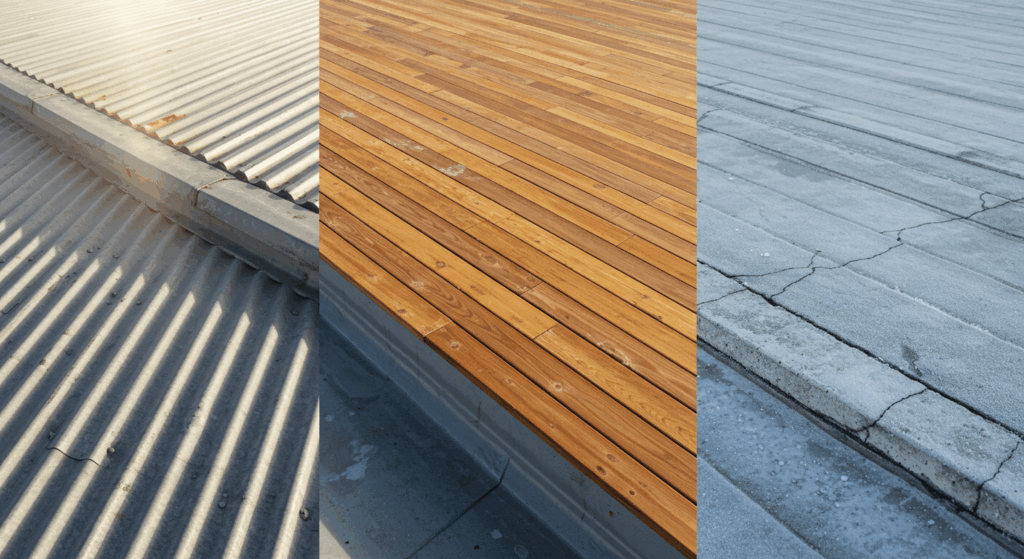

Roof Deck Materials: Comparing Steel, Wood, and Concrete Decking

Choosing the right roof deck material is one of the most important decisions in any construction or renovation project. The deck acts as the foundation for your roofing system and directly affects its strength, lifespan, and overall function. Among the most common options from steel, wood, and concrete each bring unique pros and cons that impact project outcomes.

Your choice of roof deck will affect installation cost, project timeline, maintenance needs, and energy efficiency. The National Roofing Contractors Association’s 2023 report notes that poor deck selection causes nearly 40% of early roofing system failures. That makes careful material selection essential based on your building’s needs, location, and budget.

In this guide, Premier Roofing compares the structure, cost, installation, and performance of steel, wood, and concrete decks. You’ll see how each material performs in various climates, fits with different roofing systems, and affects long-term value. Whether it’s a home or commercial project, understanding these differences helps you choose the right solution.

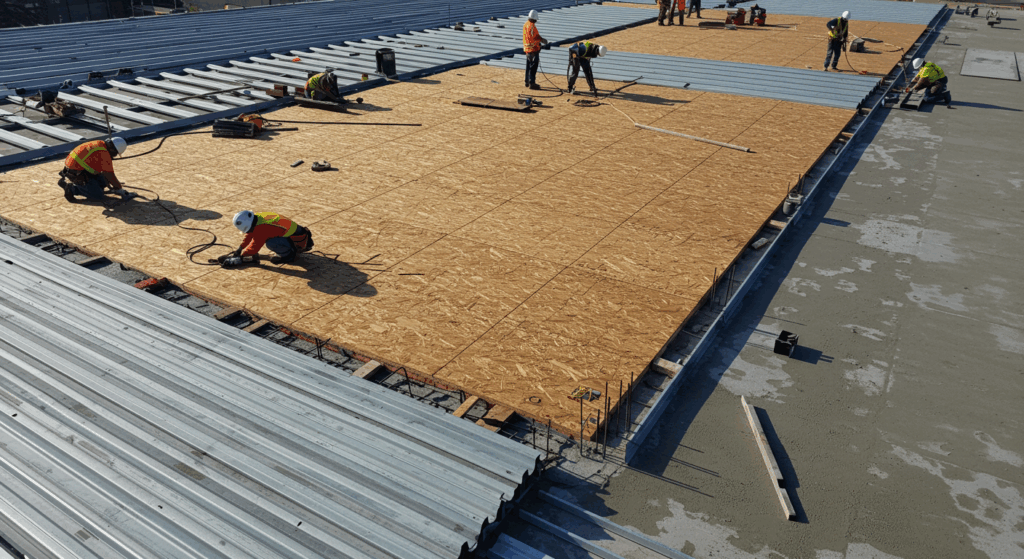

Maximize Structural Strength with Steel Roof Decking

Steel decking has become increasingly popular in commercial construction due to its exceptional strength-to-weight ratio and structural efficiency. Made from galvanized steel sheets formed into corrugated profiles, steel decking provides excellent load-bearing capacity while maintaining relatively lightweight characteristics.

The material typically ranges from 22-gauge to 16-gauge thickness, with heavier gauges offering superior strength for buildings with greater load requirements. The structural advantages of steel decking extend beyond basic load capacity. The corrugated profile creates inherent rigidity that spans longer distances between structural supports, potentially reducing the need for additional framing members.

This characteristic makes steel decking particularly valuable in commercial applications where large, uninterrupted interior spaces are desired. Installation typically involves welding or mechanical fastening to steel joists, creating a composite structural system that enhances overall building performance.

Fire resistance represents another significant advantage of steel decking systems. Unlike organic materials, steel doesn’t contribute fuel to fires and maintains its structural integrity longer under extreme heat conditions. Many steel decking products achieve fire ratings of up to two hours when properly installed with appropriate fire-resistant assemblies.

This performance characteristic often translates to reduced insurance premiums and compliance with stringent commercial building codes. However, steel decking does present certain challenges that require careful consideration.

Thermal bridging can occur where steel components connect to the building structure, potentially creating condensation issues if not properly addressed with thermal breaks or insulation strategies. Additionally, the smooth surface of steel decking may require special adhesion promoters or mechanical attachment methods when installing certain roofing membranes.

Enhance Roof Flexibility with Reliable Wood Decking

Wood remains the most common roof decking material in residential construction, with plywood and oriented strand board (OSB) representing the two primary options. These engineered wood products offer excellent versatility, ease of installation, and compatibility with virtually all roofing systems.

Standard thicknesses range from 5/8-inch to 3/4-inch for most residential applications, with thickness selection depending on joist spacing and anticipated loads. Plywood decking consists of multiple wood veneer layers bonded with waterproof adhesives, creating a strong, dimensionally stable platform.

The cross-grain construction provides excellent nail-holding power and resistance to splitting, making it ideal for shingle, tile, and metal roofing installations. OSB decking, manufactured from wood strands oriented in specific directions and bonded with resins, offers similar performance characteristics at a typically lower cost point.

The thermal properties of wood decking provide natural insulation benefits compared to steel or concrete alternatives. Wood’s lower thermal conductivity helps reduce heat transfer through the roof assembly, potentially improving energy efficiency and reducing condensation risks.

This characteristic makes wood decking particularly suitable for residential applications where comfort and energy costs are primary concerns. The installation advantages of wood decking include compatibility with standard carpentry tools and techniques. Contractors can easily cut, shape, and fasten wood decking using conventional methods, reducing labor costs and complexity.

The material also accepts various fastening systems, from traditional nails and screws to specialized roofing fasteners, providing flexibility in attachment methods for different roofing systems. Recent developments in engineered wood products have improved moisture resistance and dimensional stability.

However, wood decking still requires protection from prolonged moisture exposure, and proper ventilation design becomes critical to prevent rot, mold, and structural deterioration. Quality wood decking products now incorporate moisture-resistant treatments and improved manufacturing processes that enhance long-term performance.

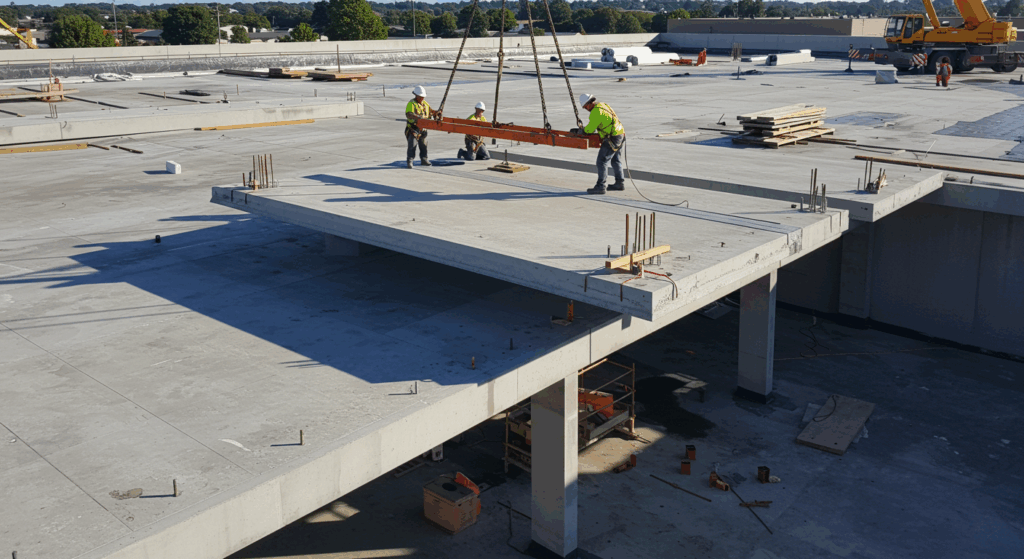

Choose Concrete Decking for Long-Term Durability

Concrete roof decking represents the premium option for maximum durability, fire resistance, and structural performance. Available in precast planks, poured-in-place systems, and lightweight concrete formulations, concrete decking offers unmatched longevity and resistance to environmental factors.

Precast concrete planks typically span 8 to 32 feet between supports, while poured systems can accommodate virtually any architectural configuration. The mass and thermal properties of concrete decking provide significant advantages in climate control and energy efficiency. Concrete’s high thermal mass helps moderate temperature fluctuations, reducing heating and cooling loads in the building below.

This characteristic proves particularly valuable in commercial buildings where energy costs represent a significant operational expense. Studies by the Portland Cement Association in 2023 show that concrete decking can reduce annual energy consumption by 15-25% compared to lightweight alternatives in moderate climates.

Fire resistance capabilities of concrete decking exceed those of other common materials by substantial margins. Concrete doesn’t burn, emit toxic gases, or lose structural integrity rapidly under fire conditions. Most concrete decking systems achieve fire ratings of three hours or more, often eliminating the need for additional fire-resistant treatments or assemblies.

This performance characteristic frequently satisfies the most stringent building code requirements for high-rise and institutional construction. At Premier Roofing, we recently completed a large commercial project where concrete decking proved essential for meeting both structural and fire safety requirements. The 200,000 square foot warehouse facility required clear spans of 60 feet with a four-hour fire rating.

Precast concrete planks provided the only viable solution that met both criteria while maintaining cost-effectiveness. The installation was completed in just three weeks, demonstrating concrete’s efficiency in large-scale applications. Concrete decking installation requires specialized equipment and expertise, particularly for precast systems that involve crane placement of heavy components.

However, the long-term benefits often justify the additional upfront complexity and costs. Properly installed concrete decking can last the entire life of the building with minimal maintenance, unlike organic materials that may require replacement or significant repairs over time.

Balance Cost and Value When Choosing Decking Materials

Initial material costs vary significantly among the three decking options, with wood typically representing the lowest upfront investment, steel falling in the middle range, and concrete commanding premium pricing.

However, accurate cost comparison requires analysis of total lifecycle expenses, including installation labor, long-term maintenance, energy implications, and replacement schedules over the building’s lifespan.

Wood decking material costs have fluctuated considerably in recent years, with OSB and plywood prices experiencing volatility due to supply chain disruptions and demand variations. As of 2024, quality 5/8-inch OSB decking typically costs $35-45 per thousand square feet, while comparable plywood ranges from $55-70 per thousand square feet.

Installation labor costs remain relatively low due to familiar installation techniques and standard carpentry skills requirements. Steel decking material costs depend heavily on gauge selection and market conditions for steel commodities. Standard 22-gauge galvanized steel decking ranges from $1.50-2.50 per square foot, with heavier gauges commanding proportionally higher prices.

Installation requires specialized crews with welding capabilities, potentially increasing labor costs compared to wood alternatives. However, the faster installation possible with steel decking often offsets higher labor rates through reduced project duration.

Concrete decking represents the highest initial investment, with precast planks typically costing $4-8 per square foot, depending on span requirements and local market conditions. Poured-in-place systems may cost $6-12 per square foot, including forming, reinforcement, and finishing. Installation requires crane rental and specialized crews, further increasing upfront costs.

However, the exceptional longevity and minimal maintenance requirements of concrete often provide superior long-term value. Energy cost implications deserve consideration in the economic analysis. Wood decking’s insulation properties can reduce heating and cooling expenses in residential applications.

Steel decking may require additional insulation to achieve comparable thermal performance. Concrete’s thermal mass provides energy benefits in commercial applications but may require higher initial heating and cooling capacity. Premier Roofing helps clients evaluate these long-term cost implications to make informed economic decisions.

Ensure Proper Installation for Lasting Roof Deck Performance

Installation procedures and requirements differ substantially among the three decking materials, affecting project scheduling, labor requirements, and quality assurance processes. Understanding these differences helps contractors and building owners plan appropriate resources and timelines for successful project completion.

Steel decking installation begins with precise measurement and layout to ensure proper alignment with structural supports. Decking sheets are typically delivered in standard widths and cut to required lengths on-site or pre-cut to specification. Installation involves positioning sheets with appropriate side and end laps, followed by welding or mechanical fastening to steel joists or beams.

Proper welding techniques and quality control ensure adequate load transfer and structural continuity. Weather conditions significantly impact steel decking installation, as welding operations require dry conditions and temperatures above freezing for optimal results.

Wind considerations become critical when handling large steel sheets at elevation, often requiring temporary bracing or installation delays during adverse conditions. Quality control procedures include visual inspection of welds, verification of fastener patterns, and confirmation of proper overlaps and edge details.

Wood decking installation follows more traditional construction practices, making it accessible to a broader range of contractors and craftsmen. Installation typically involves cutting panels to size, positioning with appropriate gaps for expansion, and fastening with ring-shank nails or screws according to the manufacturer’s specifications.

Proper fastener selection and spacing ensure adequate load transfer and prevent uplift under wind conditions. The following installation considerations are critical for wood decking success:

- Moisture content verification before installation to prevent excessive shrinkage

- Proper support spacing to prevent deflection and ensure adequate strength

- Edge support requirements at panel joints and roof perimeters

- Ventilation provisions to prevent moisture accumulation

- Protection from weather exposure during and after installation

Concrete decking installation varies significantly between precast and poured-in-place systems. Precast installation requires careful coordination with crane operations, precise placement to achieve proper bearing on supports, and grouting of joints to ensure structural continuity. Poured systems involve forming, reinforcement placement, concrete mixing and placement, and curing procedures that may extend over several days.

Select Decking That Withstands Your Local Climate

Climate conditions significantly influence the long-term performance and suitability of different roof decking materials. Temperature extremes, humidity levels, precipitation patterns, and seasonal variations all impact material behavior and durability over time.

In hot, arid climates, steel decking performs exceptionally well due to its resistance to thermal degradation and dimensional stability. However, thermal expansion and contraction cycles can create stress concentrations at connection points if not properly detailed. The high thermal conductivity of steel may also contribute to increased cooling loads in buildings without adequate insulation systems.

Wood decking faces greater challenges in humid climates where moisture infiltration and high humidity levels can promote fungal growth, rot, and dimensional instability. Modern engineered wood products incorporate improved moisture resistance, but proper ventilation and moisture management remain critical for long-term performance.

In extremely dry climates, wood decking may experience shrinkage and checking that requires attention during installation and maintenance. Concrete decking demonstrates superior performance across all climate conditions due to its inherent stability and resistance to environmental factors.

Freeze-thaw cycles present the primary concern in cold climates, particularly if water infiltration occurs through cracks or joints. Proper concrete mix design and installation practices minimize these risks and ensure long-term durability.

Coastal environments present unique challenges due to salt air exposure and high humidity conditions. Steel decking requires enhanced galvanized coatings or additional protective treatments to prevent corrosion.

Wood decking benefits from pressure treatment and moisture-resistant adhesives. Concrete decking with appropriate air entrainment and protective coatings provides excellent resistance to salt exposure and coastal weather conditions.

Frequently Asked Questions

What is the typical lifespan of each roof decking material?

Wood decking typically lasts 20-30 years with proper maintenance and favorable conditions, though high-quality plywood may extend to 40 years. Steel decking can last 50-75 years or more with adequate corrosion protection and proper installation.

Concrete decking often matches the building’s lifespan, potentially lasting 75-100 years with minimal maintenance. These lifespans assume proper installation, appropriate material selection for the application, and reasonable maintenance practices.

Can different decking materials be used with any roofing system?

While most roofing systems can be adapted to work with different decking materials, some combinations are more suitable than others. Steel decking works best with membrane roofing systems, built-up roofing, and metal roofing.

Wood decking is compatible with shingles, tiles, metal roofing, and most membrane systems. Concrete decking accommodates virtually any roofing system but may require special attachment methods for some applications. The key is ensuring proper fastening methods and compatibility between materials.

How do building codes affect roof decking material selection?

Building codes significantly influence decking material selection through fire rating requirements, structural load specifications, and seismic design criteria. Commercial buildings often require specific fire ratings that may favor concrete or steel decking.

Residential codes typically allow wood decking but specify minimum thickness and grade requirements. High-wind or seismic zones may require enhanced attachment methods or specific material properties. Always consult local building codes and a structural engineer for specific requirements.

What maintenance is required for different roof decking materials?

Steel decking requires periodic inspection for corrosion, particularly at cut edges and fastener locations, with touch-up coating as needed. Wood decking needs regular inspection for moisture damage, rot, or insect activity, plus replacement of damaged sections.

Concrete decking requires minimal maintenance beyond periodic inspection for cracks and joint sealant renewal. All decking systems benefit from proper roof maintenance to prevent water infiltration, which is the primary cause of decking deterioration.

How does roof decking material choice affect building energy efficiency?

Wood decking provides natural insulation properties that can reduce heat transfer through the roof assembly. Steel decking has high thermal conductivity and may require additional insulation to achieve comparable thermal performance.

Concrete decking offers thermal mass benefits that help moderate temperature swings and can reduce peak heating and cooling loads. The overall impact depends on climate, insulation design, and building use patterns. Energy modeling during design helps optimize the complete roof assembly for maximum efficiency.

Plan Your Roof Decking Project with Trusted Expertise

Selecting the appropriate roof decking material requires careful evaluation of structural requirements, environmental conditions, budget constraints, and long-term performance expectations. Steel decking excels in commercial applications requiring long spans and fire resistance, while wood decking remains the versatile, cost-effective choice for most residential projects.

Concrete decking provides unmatched durability and performance for demanding applications where longevity justifies a higher initial investment. Consider consulting with roofing professionals who can evaluate your specific requirements and recommend the optimal solution for your project’s unique needs and circumstances.

About Premier Roofing

Our company delivers complete roofing solutions with over 15 years of experience serving residential and commercial clients in the region. We handle full roof deck installation and replacement, including steel, wood, and concrete systems. Our certified roofing team blends structural engineering with proven installation methods to ensure lasting roof deck performance.

At Premier Roofing, we help clients choose the right decking material by evaluating building needs, environmental factors, and budgets. Our services include structural analysis, material selection, and installation practices that optimize performance and value. We’ve completed over 500 roof deck projects, from home upgrades to large-scale commercial builds.Contact our team today to discuss how our roofing expertise can help you select and install the ideal roof decking system for your project. Schedule a consultation to learn more about our comprehensive roofing services and how we’ve helped clients achieve superior roof performance and long-term value.