Types of Roof Decking for Flat Roofs: Pros and Cons

Choosing the right decking for a flat roof can mean the difference between years of solid protection and costly future repairs. Unlike sloped roofs, flat roofs rely on strong, moisture-resistant materials to prevent sagging, leaks, and early failure.

Decking acts as the foundation of your entire roofing system. It must handle membrane loads, equipment, foot traffic, and stresses from weather and temperature changes. With so many options available, each with its pros and cons, it’s important to understand how they perform in real-world settings.

This guide breaks down the most common roof decking types used in flat roof construction. You’ll learn how each material performs, how it’s installed, and what to expect long-term. Whether you’re building new or replacing an old roof, Premier Roofing is here to help you choose the best decking for your budget and building needs.

Maximize Strength with Plywood Decking for Flat Roofs

Plywood remains one of the most versatile and widely used decking materials for flat roof applications. This engineered wood product consists of multiple thin wood veneers bonded together with adhesive, creating a strong and dimensionally stable substrate for roofing systems.

The primary advantage of plywood decking lies in its excellent strength-to-weight ratio and ease of installation. Standard 4×8-foot sheets can be quickly installed by roofing crews, and the material accepts fasteners well without splitting. For flat roof applications, contractors typically specify 5/8-inch or 3/4-inch thickness to provide adequate structural support and minimize deflection between joists.

However, moisture resistance represents plywood’s greatest weakness in flat roof applications. Even exterior-grade plywood can experience delamination and decay when exposed to persistent moisture conditions. A commercial building in Phoenix experienced significant plywood deck deterioration after just eight years when inadequate membrane installation allowed water infiltration around HVAC penetrations.

Modern plywood manufacturers have developed improved formulations specifically for roofing applications. These products feature enhanced moisture resistance and stronger adhesive systems that better withstand the thermal cycling common in flat roof environments.

When properly installed with appropriate moisture barriers, quality plywood decking can provide 20-25 years of reliable service in most climate conditions.

Lower Costs with OSB Decking Without Sacrificing Performance

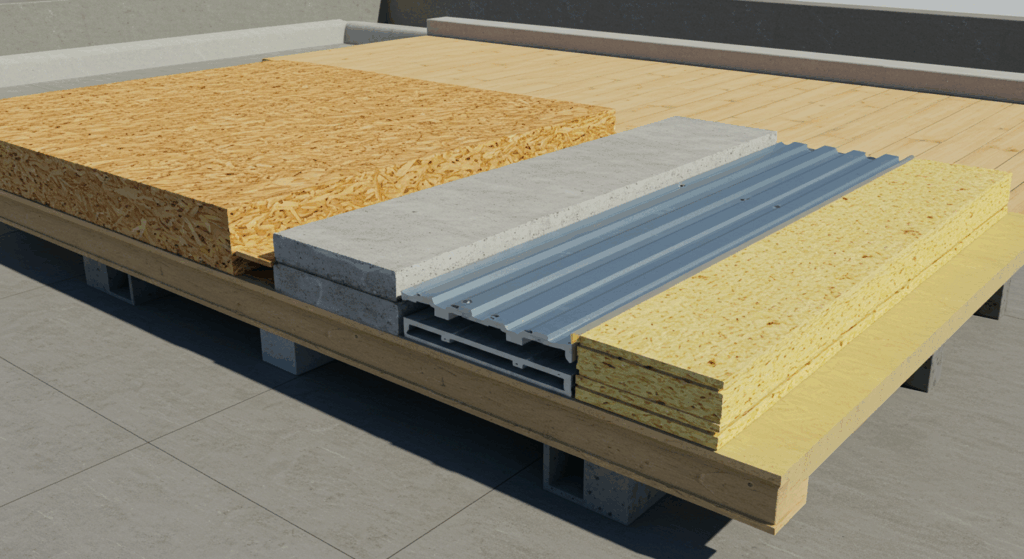

Oriented Strand Board has gained significant market share in flat roofing applications due to its cost-effectiveness and consistent manufacturing quality. OSB consists of wood strands arranged in specific orientations and bonded with waterproof adhesives under high pressure and temperature.

The manufacturing process creates a uniform product with fewer voids and defects compared to traditional plywood. This consistency translates to more predictable performance and easier installation for roofing contractors. OSB also typically costs 15-20% less than comparable plywood grades, making it attractive for budget-conscious projects.

Installation characteristics favor OSB in many applications. The material’s consistent density and strand orientation provide excellent holding power for roofing fasteners, reducing the risk of pull-through failures during high wind events.

A recent study by the National Roofing Contractors Association found that properly installed OSB decking exceeded code requirements for wind uplift resistance by an average of 18%. Moisture sensitivity remains a concern with OSB, though modern formulations have significantly improved in this area.

Exposure to moisture can cause edge swelling and surface roughening that may telegraph through single-ply membrane systems. Premier Roofing recommends specifying OSB products specifically rated for roofing applications, which include enhanced moisture resistance and improved edge sealing.

Strengthen Commercial Roofs with Fire-Resistant Steel Decking

Steel decking dominates the commercial flat roofing market due to its superior structural properties and fire resistance. These corrugated steel panels span between structural supports, creating a strong platform for insulation and membrane installation while remaining relatively lightweight.

The structural advantages of steel decking are substantial. Form decks can span greater distances between supports compared to wood products, potentially reducing the number of structural beams required.

This characteristic proves particularly valuable in retrofit applications where existing structures may have limited load capacity. Steel decking also provides excellent diaphragm action, helping distribute lateral loads throughout the building structure.

Fire resistance represents another significant advantage of steel decking systems. Unlike combustible wood products, steel decks contribute to overall building fire safety and may reduce insurance premiums for commercial properties. The material also resists pest damage and won’t support mold growth, addressing common concerns in humid climates.

However, steel decking presents unique installation challenges that require specialized expertise. Thermal bridging can create condensation issues if not properly addressed with appropriate insulation strategies. Additionally, the corrugated profile requires careful detailing around roof penetrations and perimeter conditions to ensure proper membrane installation.

Increase Load Capacity with Durable Concrete Decking

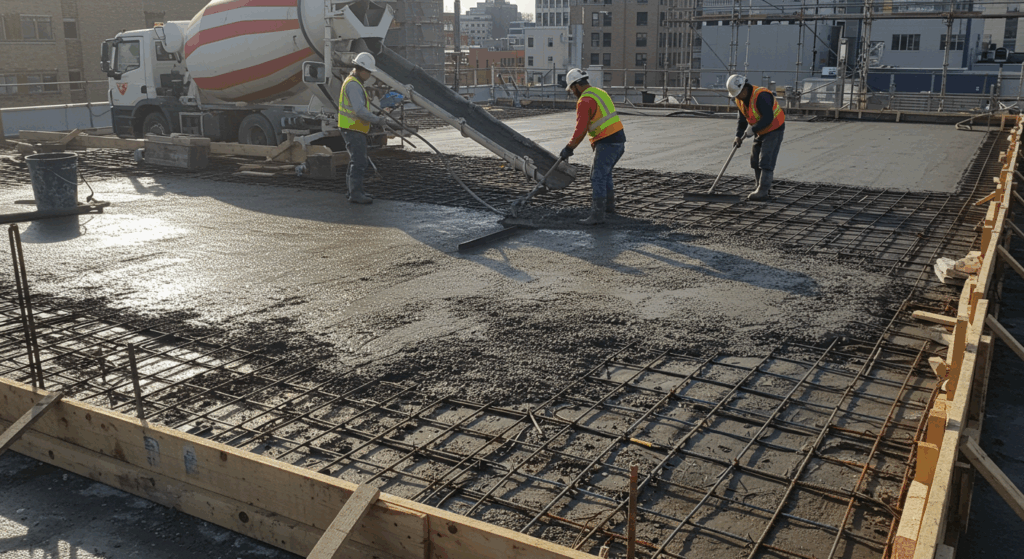

Concrete decking provides the ultimate in structural strength and durability for flat roof applications. Whether cast-in-place or precast, concrete decks offer exceptional load-bearing capacity and virtual immunity to moisture-related deterioration.

Cast-in-place concrete allows for complete customization of deck thickness and reinforcement to meet specific structural requirements. This flexibility proves valuable for roofs supporting heavy equipment loads or requiring unusual spans. The monolithic construction also eliminates joints that could become moisture infiltration points in other decking systems.

Precast concrete planks offer faster installation while maintaining many of the concrete’s durability advantages. These factory-manufactured components arrive on-site ready for immediate installation, reducing weather delays and construction time. Modern precast systems include integrated insulation options that can improve overall roof system thermal performance.

The primary limitation of concrete decking involves its substantial weight. Building structures must be designed to accommodate concrete’s high dead load, which may increase foundation and framing costs. A typical 4-inch concrete deck weighs approximately 50 pounds per square foot compared to 2-3 pounds for wood decking systems.

Boost Energy Efficiency with Insulation Board Decking

In certain applications, rigid insulation boards can serve dual roles as both thermal barrier and structural deck. This approach, commonly called “nailable deck” construction, involves installing multiple layers of high-density insulation boards over structural supports.

Polyisocyanurate boards represent the most common choice for nailable deck applications. These rigid foam boards provide excellent thermal performance while offering sufficient structural capacity for membrane installation and light foot traffic. The installation process involves mechanically fastening the first layer to structural supports, then adhering subsequent layers with compatible adhesives.

The thermal advantages of insulation board decking are substantial. By eliminating thermal bridging through structural members, these systems can achieve significantly higher R-values than conventional deck-over-insulation approaches. This improved performance often allows building owners to meet increasingly stringent energy codes with thinner overall roof assemblies.

Installation requirements for nailable deck systems demand careful attention to board joints and fastening patterns. Premier Roofing emphasizes the importance of staggering joints between layers and following manufacturer specifications for fastener spacing and penetration depth. Inadequate installation can result in deck movement and membrane failures.

Choose Lightweight Strength with Gypsum Concrete Decking

Gypsum concrete offers unique advantages for flat roof decking applications where lightweight concrete performance is desired without the weight penalty of traditional Portland cement systems. This material consists of gypsum cement mixed with lightweight aggregates and water to create a pourable deck system.

The lightweight characteristics of gypsum concrete make it attractive for retrofit applications where structural capacity is limited. A typical 2-inch gypsum concrete deck weighs approximately 15 pounds per square foot, significantly less than conventional concrete, while providing superior structural performance compared to wood products.

Installation of gypsum concrete decking requires specialized equipment and experienced crews. The material must be mixed and placed according to strict specifications to achieve proper strength and surface characteristics. Weather conditions during installation are critical, as rain or freezing temperatures can compromise the curing process and final performance.

Moisture sensitivity represents the primary limitation of gypsum concrete decking. Extended exposure to water can cause deterioration and strength loss, making proper membrane installation and maintenance critical for long-term performance. However, when protected by quality roofing systems, gypsum concrete decks have provided decades of reliable service in commercial applications.

Evaluate and Select the Right Decking Material for Your Flat Roof

Selecting the optimal decking material requires careful evaluation of multiple factors, including structural requirements, climate conditions, building use, and budget constraints. Each material offers distinct advantages that may favor its selection in specific applications.

For residential and light commercial applications, wood products typically provide the best balance of cost and performance. OSB offers budget advantages while plywood provides superior moisture resistance for critical applications. Both materials require proper installation techniques and quality roofing systems to achieve their full service life potential.

Commercial projects often benefit from the superior performance characteristics of steel or concrete decking systems. These materials provide enhanced structural capacity, fire resistance, and durability that justify their higher initial costs through reduced maintenance and longer service life.

Climate considerations significantly influence decking selection decisions. High-humidity environments favor moisture-resistant materials like steel or concrete, while areas with extreme temperature variations require careful attention to thermal expansion characteristics. Buildings in seismic zones may benefit from the ductility advantages of wood or steel systems over rigid concrete decks.

Frequently Asked Questions

What thickness of plywood is recommended for flat roof decking?

For flat roof applications, 5/8-inch plywood represents the minimum thickness for most residential applications, while 3/4-inch provides better performance and is preferred for commercial projects.

The thicker material reduces deflection between joists and provides better fastener holding power for roofing systems. Building codes may specify minimum thicknesses based on joist spacing and expected loads.

How does OSB compare to plywood for moisture resistance in flat roofing?

Modern OSB formulations have significantly improved moisture resistance compared to earlier products, but plywood generally maintains an advantage in this area. Both materials require proper installation with appropriate vapor barriers and quality roofing systems to prevent moisture infiltration.

The key difference lies in how they respond to moisture exposure, with plywood typically showing less dimensional change and surface deterioration.

What are the main advantages of steel decking for commercial flat roofs?

Steel decking offers superior structural capacity, allowing longer spans between supports and excellent diaphragm action for lateral load distribution. It provides inherent fire resistance, won’t support mold growth or pest infestation, and maintains dimensional stability across wide temperature ranges.

These characteristics make steel decking particularly valuable for commercial applications with heavy equipment loads or stringent fire safety requirements.

Can insulation board systems replace traditional structural decking?

High-density polyisocyanurate boards can serve as nailable decking in certain applications, but this approach requires careful engineering evaluation and proper installation techniques.

The system works best over closely spaced structural supports and is limited to applications with moderate load requirements. Professional design and installation are essential to ensure adequate structural performance and long-term reliability.

What factors should determine decking material selection for flat roofs?

Key selection criteria include structural load requirements, climate conditions, building fire safety needs, installation timeline, and budget constraints. The intended building use, maintenance accessibility, and local building code requirements also influence material selection. Professional evaluation of these factors ensures optimal decking choice for specific project requirements and long-term performance expectations.

Plan Your Flat Roof Project with Informed, Reliable Guidance

Selecting the appropriate roof decking material for flat roof applications requires careful consideration of structural requirements, environmental conditions, and long-term performance expectations.

While wood products like plywood and OSB offer cost-effective solutions for many residential and light commercial applications, steel and concrete decking systems provide superior performance for demanding commercial environments.

Understanding each material’s strengths and limitations enables informed decision-making that optimizes both initial investment and long-term value. Professional consultation ensures proper material selection and installation techniques that maximize your flat roof system’s performance and service life.

About Premier Roofing

Premier Roofing has over 15 years of experience in flat roof construction and restoration for both commercial and residential clients. We offer full-service roofing solutions, including deck evaluation, membrane installation, and preventive maintenance. Our certified professionals blend structural engineering with advanced roofing expertise to ensure top performance across all roof types.

We focus on precision and craftsmanship, using the latest materials and techniques to deliver dependable results. With deep experience in plywood, OSB, steel, concrete, and specialty decks, we recommend the right fit for each project’s needs. We’ve helped hundreds of clients achieve long-lasting flat roofs through smart material choices and expert installation.Contact our team today to discuss how our flat roofing expertise can help you select the optimal decking material for your project. Schedule a consultation to learn more about our comprehensive roofing services and how we’ve helped clients achieve superior performance and value from their roof investments.